Robot 3D Printer: A Small Guide to Robotic Arm for 3D Printing

Robot 3D printing is a combination of a 3D printer head extruding materials with a multi-axis robotic arm. Due to this, it can create a much more flexible 3D printer in comparison to a conventional model. Due to the high movement range of this robot 3D printer, this technology is used for large projects.

In this blog, you will learn more about the robotic arm technology for 3D printing, such as its benefits, the industries that rely on it, and how it works for 3D printing.

Introduction to a Robotic Arm for 3D Printing

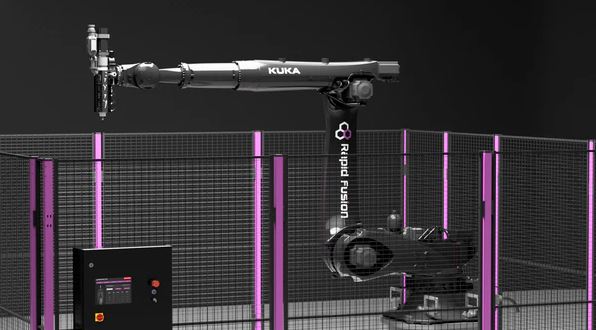

A robotic arm for 3D printing is a robotic arm manufacturing type. An articulated, industrial robotic arm is utilized for the movement of a printhead around to additively manufacture a component. A robotic arm is also called robot additive manufacturing (RAM). A robotic arm is capable of using established ways of 3D printing like directed energy deposition (DED) or fused deposition modeling (FDM). However, the feed material is given a position by a robotic arm instead of a gantry.

Benefits of the Robotic Arm for 3D Printing Projects:

Robot arm 3D printing comes with many advantages, such as:

• A robot 3D printer for 3D printing instantly lets larger-scale models (>1m in any dimension) get printed in comparison to a typical self-contained 3D printer. If the robot can move, the models that are as large as 30m in one dimension get printed.

• The 5-or-6-axis movement offers freedom of movement for the 3D printing head. It provides the capability of tracing complicated paths to build components.

• Due to robotic arms, most models can be built without support because of the freedom of movement of the print head. However, if one wants to completely avoid support on some models, the build platform may be required to move as well, to let the model be reoriented.

• A robotic arm can be used with various 3D printing fixtures. In fact, it can be fitted with those 3D printing fixtures that can let multiple feed materials get used like CBAM or WAAM.

How does a Robot Additive Manufacturing Work for 3D Printing?

A robot arm for 3D printing works like a typical industrial robot arm, but a printhead is set to the end of the arm. The robotic arm has multiple joints. Each of these joints offers some freedom of movement, in total offering five- or six-axis control. Due to this, the robot can tilt, move, and place the printhead throughout a range of potential positions. Thus, the robot arm moves the printhead over a component so that it can print multiple layers and contours.

What Industries do Rely on a Robot Arm for 3D Printing?

Due to the various benefits of using a robot 3D printer for 3D printing, various industries are using this technology. Let’s look at the industries that have adopted a robot arm:

Construction Industry:

If it’s about this, the construction industry deserves the first place. The industry relies on robotic arms to create intricate architectural designs and large structures in a convenient way.

Healthcare Industry:

The healthcare industry is making giant steps to learn about the potential of 3D printing with robotic arms for tailored solutions. However, the sector still needs careful human supervision. The sector uses this technology for the creation of prosthetics, surgical tools, etc.

Automotive Industry:

The robot 3D printer method is used by car manufacturers for parts production. Using this technology allows the manufacturers to ensure quicker turnarounds and tailored designs. The use of a large build volume 3D printer is often required in this industry.

Mechanical Engineering:

Robotic arms are very famous for their adaptability and precision. Due to this, this industry considers this technology a huge asset. Using a robotic arm, the industry gets benefits like prototyping, testing mechanical components, and producing complicated parts.

Conclusion

Robot 3D printing uses a 3D printer head that extrudes materials with a multi-axis robotic arm, which is why the robot 3D printer is much more flexible than a conventional model.

Many industries, such as healthcare, automotive, construction, and the like are using this technology.