Exploring the Rise of Industrial FDM Printers in the UK: A Game Changer

As with any technological shift of this magnitude, the phenomenon of 3D printing has been gradually changing industries at home and abroad. Fused Deposition Modeling is among the most crucial 3D printing technologies, especially in industrial production systems. This paper examines that with such fantastic viabilities and widespread applications, industrial FDM printers are revolutionizing the manufacturing industries in the UK. It is now time to expand on why 3D printers are so important and their influence on one or another field. One of the most popular 3D printing techniques is fused filament fabrication, often known as fused deposition modeling (FDM®) or FFF. To make a three-dimensional item, FDM printers expel thermoplastic filament over a build plate in a succession of layers.

Thus, identifying what sets Industrial FDM printers unique is by far one of the most important tasks for now. Through this blog, let us understand what makes 3D printers so unique, what are the possible challenges in using them, and what role they will play in the future.

What Makes Industrial FDM Printers Unique?

Enhanced Material Options

In general, Industrial FDM printers have more opportunities in a wider choice of materials than consumer FDM models. These are generally the specialty of thermoplastics like ABS, PLA, and some other top-notch composite materials like carbon fiber reinforced filament types. Due to this flexibility, the choice of the material for manufacturing can be made depending on what is required, strength, flexibility, or ability to endure certain environmental conditions.

Larger Build Volumes

Another advantage of industrial FDM printers is the large build volumes that can be observed in the case of this equipment. It is especially useful for constructing large prototypes or making large-scale parts, which are not assembled from several pieces and, thus, enhance the productivity of a manufacturing process.

Precision and Reliability

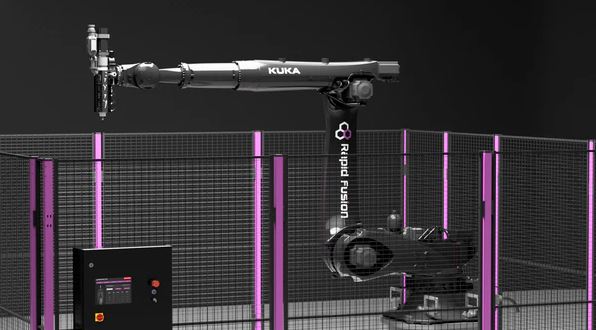

Fused Deposition Modeling industrial printers are designed for accuracy with a range of reliable and repeatable print quality. They utilize features such as heated built chambers and AC to control the whole process and achieve great performance. It goes down to the extent of micrometers in the manufacturing process, which is critical in industries such as aerospace, automotive, and the manufacture of medical equipment.

Challenges and Future Directions

Although industrial FDM printers are more advantageous some limitations have to be considered. A major problem is expensive and, therefore, unavailable premium machines and materials that can make it difficult for smaller businesses. Also, quality control and post-processing are the factors that remain as challenges; quality and consistency are works in progress.

Prospective for industrial FDM printing in the future: all in all, the use of FDM printing in the industrial sector is highly probable in the future in the UK. With the continuous improvement of printer hardware, the materialization of advanced material science, and improved software algorithms, the limitations of FDM printers and the ability of the method they offer should be easily solved. This way, as these advancements go on, it is possible to foresee even more unique uses of the concept and higher incorporation of it across various spheres of business.

Conclusion

3D printers in UK are the revolution in the manufacturing sector. The kind of work they deliver; high quality, durability, and accuracy within the fastest time possible is changing the face of several industries. It’s not possible to imagine today’s aerospace and healthcare sectors without including this technology in the list of crucial ones. All the same, as the innovation goes on, industrial FDM printers will play a more crucial part in determining the future of manufacturing.

From our findings, any business planning to implement this technology should ensure that they update themselves with the latest technologies in FDM while ensuring they get the best Industrial FDM printers if they want to counter other competitors in the ever-shifting market.